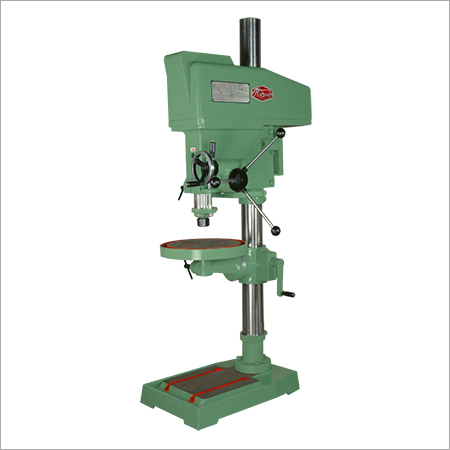

All Geared Auto Feed Pillar Drilling Machines

Price 170000.00 INR/ Unit

All Geared Auto Feed Pillar Drilling Machines Specification

- Condition

- New

- Dimension (L*W*H)

- 900 mm x 600 mm x 1900 mm

- Noise Level

- Low

- Features

- All Geared, Auto Feed, Heavy Duty Construction, High Precision

- Frequency

- 50 Hz

- Diameter

- 38 mm

- Table Size

- 400 mm x 400 mm

- Motor Power

- 2 HP 3 HP

- Machine Type

- Pillar Type

- Cutting Area

- 38 mm diameter

- Spindle Speed

- 90 to 1400 RPM

- Product Type

- All Geared Auto Feed Pillar Drilling Machine

- Material

- Cast Iron & Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- CNC Or Not

- Not CNC

- Control System

- Manual Gear

- Voltage

- 380V / 415V

- Power

- 2 HP 3 HP

- Power Source

- Electric

- Weight (kg)

- 600 kg (approx)

- Capacity

- 38 mm Drilling Capacity

- Color

- Industrial Blue / Grey

- Usage & Applications

- Drilling, Reaming, Tapping Operations on Metal, Wood & Plastic

- Coolant Pump

- Fitted

- Number of Spindle Speeds

- 8

- V-Belt Size

- B-56

- Drilling Depth

- 250 mm

- Max Distance Spindle to Table

- 800 mm

- Spindle Travel

- 250 mm

- Column Diameter

- 110 mm

- Swing

- 700 mm

- Base Size

- 650 mm x 400 mm

- Quill Diameter

- 63 mm

- Tapping Capacity

- M20

- Feed Range

- 0.05 0.30 mm/rev

- Spindle Nose Taper

- MT4

All Geared Auto Feed Pillar Drilling Machines Trade Information

- Minimum Order Quantity

- 1 Set

- Payment Terms

- Cheque

- Supply Ability

- 1 Set Per Day

- Delivery Time

- 2 Days

- Main Domestic Market

- All India

About All Geared Auto Feed Pillar Drilling Machines

since 1996, we are affianced in manufacturing, exporting and supplying an exceptional quality array of Auto feed Pillar Drilling Machines. In compliance with the international quality standards, these machines are manufactured by making use of optimum quality components and the pioneering techniques by our adroit professionals. Used for hassle free drilling, these machines are also tested on defined parameters of quality. Apart from this, the offered Auto Feed Pillar Drilling Machines can be purchased at reasonable prices from us.

Product Details:

| Type | Radial drill machine |

| Capacity | 42 |

| Drill Depth | 250 |

| Drilling Diameter | 42 |

| Brand | PRAKASH |

| Model | DC411 |

| Automatic Grade | Automatic |

PRAKASH DC411 - Double Column Allgeared Autofeed Radial Drill Machine is best suitable for heavy job load with heavy drilling.

With biggest working range in this category of machines, this model gives maximum coverage for the job.

Callback

Features:

Hassle-free performance

Long service life

High mechanical strength

High efficiency

Robust and Versatile Drilling Solution

With sturdy construction and advanced auto feed features, this pillar drilling machine is perfectly suited for multiple industrial tasks. Its high spindle travel and wide base provide stability, while eight speed options allow fine-tuning for various materials. Designed for durability and accuracy, this machine facilitates precise drilling, tapping, and reaming.

Superior Performance in Metalworking

Engineered for heavy-duty operations, this all-geared pillar drilling machine handles demanding applications on metal, plastic, and wood. The spindle nose taper MT4 and built-in coolant pump contribute to longer tool life and superior finishing, while the large swing and powerful motor accommodate larger workpieces effortlessly.

FAQ's of All Geared Auto Feed Pillar Drilling Machines:

Q: How does the auto feed mechanism improve drilling efficiency?

A: The auto feed feature ensures consistent feed rates, allowing smoother drilling and improved precision. Operators do not have to manually advance the spindle, which helps prevent irregular feed and reduces fatigue during extended use.Q: What materials can the All Geared Pillar Drilling Machine process?

A: This machine is capable of drilling, tapping, and reaming on metals (like steel and cast iron), plastics, and wood, making it ideal for a wide variety of industrial tasks.Q: When should I select a spindle speed between 90 and 1400 RPM?

A: The spindle speed choice depends on material hardness, drilling diameter, and desired finish. Use lower speeds for tougher materials and larger drills, and higher speeds for softer materials and smaller holes to optimize drilling performance.Q: Where should this machine be installed for optimal use?

A: Install the pillar drilling machine on a stable, flat floor within a well-ventilated workshop. Ensure enough clearance for the base (650 mm x 400 mm) and ease of access to electrical power supply (380-415V). Proper positioning enhances operational safety and productivity.Q: What is the tapping capacity of this machine and how is it beneficial?

A: The machine's tapping capacity is M20, allowing users to precisely thread holes up to 20 mm in diameter. This supports versatile component fabrication, especially in metalworking operations requiring threaded parts.Q: How does the fitted coolant pump contribute to machine operation?

A: The integrated coolant pump minimizes heat buildup and lubricates the drilling process, which prolongs tool lifespan, enhances drilling accuracy, and prevents material warping during heavy-duty machining.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Heavy Duty Pillar Drilling Machine Category

Auto Feed Pillar Drilling Machines

Price 157000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

CNC Or Not : Normal

Automatic Grade : Automatic

Product Type : Pillar Drill Machine

Industrial Pillar Drilling Machine

Price 23000 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

CNC Or Not : Normal

Automatic Grade : Manual

Product Type : Pillar Drill Machine

Pillar Drill Machine

Price 68500 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

CNC Or Not : Normal

Automatic Grade : Manual

Product Type : Pillar Drill Mahcine

25 mm Cap Back Geared Fine Feed Pillar Drill Machine

Price 42800 INR / Unit

Minimum Order Quantity : 1 Unit

Computerized : No

CNC Or Not : Normal

Automatic Grade : Manual

Product Type : Pillar Drill Machin

GST : 24AAFCP7961F1ZA

|

PRAKASH ENGITECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry