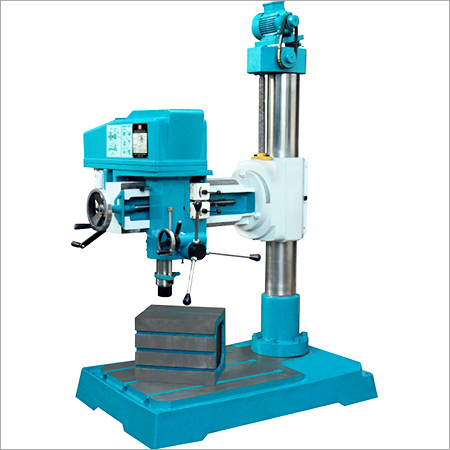

Double Column Radial Drill Machine

Price 415000.00 INR/ Unit

Double Column Radial Drill Machine Specification

- Spindle Speed

- 70-1520 RPM

- Dimension (L*W*H)

- 550x450x400 Millimeter (mm)

- Computerized

- No

- Automatic Grade

- Automatic

- CNC Or Not

- Normal

- Voltage

- 440 Watt (w)

- Power

- 2000 Watt (w)

- Power Source

- AC 3-Phase

- Capacity

- 42 mm Kg/hr

Double Column Radial Drill Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Payment Terms

- Cheque

- Supply Ability

- 1 Unit Per Day

- Delivery Time

- 4 Week

- Main Domestic Market

- All India

About Double Column Radial Drill Machine

This standard quality Double Column Radial Drill Machine is equipped with numerous functions such as panel arrangement of mechanical as well as electrical controls. It is highly appreciated for its longer working life, smooth functioning, optimum performance and corrosion resistance. The said machine is manufactured by using best grade components and modern technologies for providing our customers with a reliable product. Moreover, Double Column Radial Drill Machine can be easily customized in different specifications, dimensions and designs according to the requirement of our client.

42 MM DOUBLE COLUMN TYPE Radial Arm Drilling Machine

| No | Description | DC - 410 |

| Capacity | Drilling In Mild Steel | 42 ( 1 5/8") |

| Drilling in Cast Iron | 50 | |

| Rough Boring in Mild Steel | 60 | |

| Tapping in Mild Steel | 25 | |

| Drilling Head | Spindle Taper | MT-4 |

| Spindle Travel | 225 | |

| Spindle Speed (RPM x Steps) |

12 steps 70, 125, 180, 245, 290, 325, 380, 490, 650, 800, 1100, 1520 |

|

| Diameter of RAM (Quill) | 78 | |

| No. of Spindle Auto feed Ranges (MM/REV) | 4 steps 0.06, 0.12, 0.20, 0.30 |

|

| Working Range | Max / Min Distance Spindle Nose to Base | 1135 / 395 |

| Vertical Travel of Arm | 740 | |

| Max / Min Distance Spindle Center to Column | 1020 / 275 | |

| Horizontal Travel of Arm | 745 | |

| Max Drilling Radius | 1133 | |

| Machine Measurement (LxBxH) | 1600 x 850 x 2190 | |

| Diameter of Column | 225 | |

| Work Table | 500 x 450 x 400 | |

| Coolant Tank | 770 x 430 x 145 50 Liters |

|

| Power | Drill Head Motor | 2 HP(1.5 KW) 960 RPM (Single Speed Motor) |

| Elevating Motor | 1 HP(0.75 KW) 960 RPM |

Specification of Machine :

- Left hand operation with ergonomic world class design.

- Independent locking of Drill Head With Arm, Arm With Sleeve And Sleeve With Column for easy setting.

- Use of high grade - fine grain materials and precision manufacturing guarantee long life of machine.

- Easily accessible front panel arrangement of electrical and mechanical controls.

- More Wider base for working area.

- Coolant tank of 50 liters.

- Rigid box type construction.

- More Wider Base for better work piece grip.

- 4 " long Lifting screw nut made up of brass.

- Double column type structure with Dia 225 MM and INSIDE RIBS for more rigidity and smooth movement.

- Arm and Column rigidly built with reinforcement ribs to reduce distortion, to give high capacity and lasting accuracy.

- Completely Oil bath gear box with 12 spindle speed steps with near geometric progression for the optimum use of machine.

- All gears gearbox are made up of NiCr Steel with hardness of 50-55 HRC with thickness of 15 mm.

- All shafts made of NiCr alloy steel with hardness 55 HRC.

- All Four splines and six splines of shafts are GROUND on Spilne Grinding Machine.

- Spildle & spindle ram(Quill) are made up OF NiCr Steel WITH FINAL HARDNESS OF 55 HRC

- Spindle is designed with 4 Nos of Bearing with Taper, Thrust and Ball Bearings.

- Bearing sizes are internal ground.

- Pinion supported through bearings.

- Head stock is provided with HIGH GRADE CAST IRON LINER BUSH like in automobile engines for easy sliding movement of RAM and very long life. Also it ensures interchangeability when replacing after wear out.

- 4 auto feed near geometric progression for all processes to be done like drilling, reaming, boring, etc.

- Overload Safety Clutch System for tool protection and machine protection.

- Spindle auto-stop with travel adjustment

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Radial Drill Machines Category

50mm All Geared Radial Drill Machine

Price 550000.0 INR / Number

Minimum Order Quantity : 1 Number

Automatic Grade : Automatic

Product Type : Radial Drill Machine

Computerized : No

CNC Or Not : Normal

40 mm All Geared Auto Feed Radial Drilling Machines

Price 250000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Product Type : Radial Drill Machine

Computerized : No

CNC Or Not : Normal

Autofeed Radial Drill Machine

Price 250000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Product Type : Radial Drilling Machines

All Geared Fine Feed Radial Drilling Machines

Price 140000.00 INR / Unit

Minimum Order Quantity : 1 Piece

Automatic Grade : Manual

Product Type : Radial Drill Machine

Computerized : No

CNC Or Not : Normal

GST : 24AAFCP7961F1ZA

|

PRAKASH ENGITECH PVT. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry